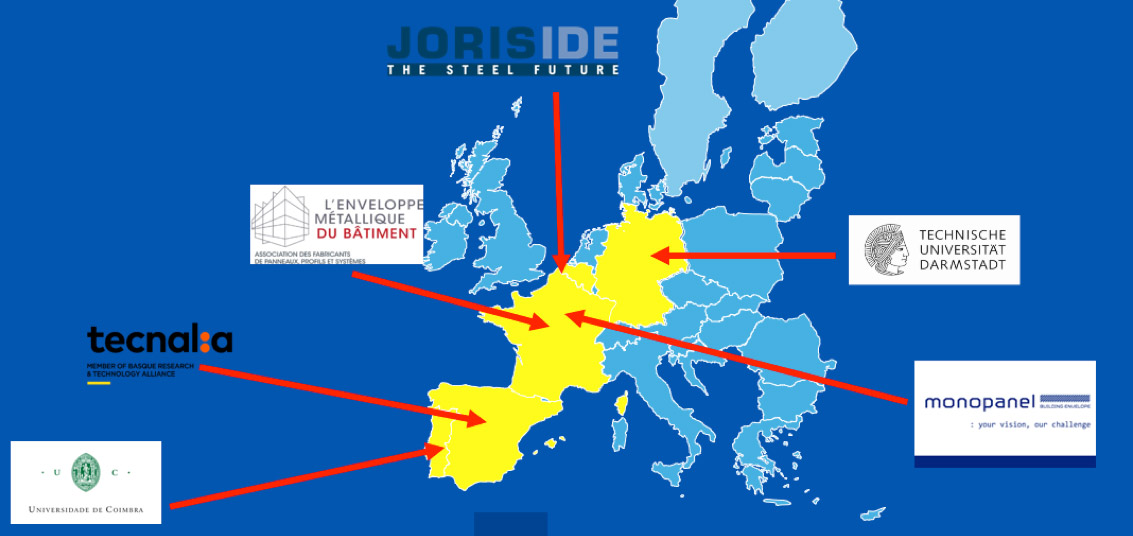

6 partners from 5 different countries

L’Enveloppe Métallique du Bâtiment

L’Enveloppe Métallique du Bâtiment (EMB) is a trade association that groups more than 95% of the French metal envelope manufacturers.

EMB carries out the traditional tasks of a professional organization such as representing the interests of its members, drafting the profession’s standards, monitoring legal developments, etc …

In addition, and in particular through its Institute, EMB runs tests, studies and R & D projects of collective interest, produces collective and individual EPD (e.g 41 EPD collectives are accessible on the INIES database), develops training courses (60 programs available), assists manufacturers in drafting technical dossiers in order to obtaining conformity, etc …

Please find further information on our website

www.enveloppe-metallique.fr

www.institut-enveloppe-metallique.fr

For the INCSEB project, l’EMB has several roles.

Firstly, l’EMB is the project coordinator, ensuring that the project runs properly (meeting deadlines, organize project meetings, etc.) and responsible for relations with the EU Commission (producing reports, etc).

EMB then carries out a number of specific tasks for the project:

- Check the consistency of the deliverables produced

- Determine the indicators of life cycle assessment (LCA) for the five systems studied

- Assess the economic relevance of the five systems

- Prepare a series of three draft amendments for sandwich panels and double skin systems to be sent to the relevant TC committees

- Organize a dedicated industrial workshop

Technische Universität Darmstadt

Steel Construction Department at the Technical University of Darmstadt

The Steel Construction Department, led by Prof. Dr.-Ing. Jörg Lange, features over 25 years of expertise in both experimental and numerical analysis of sandwich panels for structural engineering. Our primary focus lies in research and education within the field of steel and lightweight construction, developing the engineers of tomorrow, see Fig. 1 and 2. Key research areas include sandwich panels, additive manufacturing, and steel construction connections.

Equipped with state-of-the-art experimental facilities, accredited by the German Accreditation Body (DAkkS), we are capable of comprehensive characterization of sandwich panels. Our team of research and technical assistants actively engages in advancing the field, with a particular emphasis on sandwich panels up to 8 meters in length, tested in our ultimate load testing rig.

Certified by both the German Accreditation Body (DAkkS) and the German Institute for Building Technology (DIBt), our department serves as a certification body for various construction products and processes. Our testing laboratory, recognized by DIBt, specializes in mechanical testing of sandwich panels and is accredited by DAkkS for testing in the field of sandwich technology.

Please find further information on our website

https://www.stahlbau.tu-darmstadt.de/fachgebiet/FG_Stahlbau.de.jsp

LinkedIn

Key tasks of TUDa within the InCSEB project

Within the ongoing InCSEB project, our responsibilities encompass the evaluation and analysis of three developed envelope systems with sandwich panels. These roof and façade panels, featuring wood fiber cores, undergo several mechanical testing according to EN 14509:2013 standards. Our tests range from material property assessments through small-scale tests (see Fig. 3) to full-scale load-bearing capacity evaluations. Additionally, durability tests under varying temperature and humidity conditions are conducted to ensure performance longevity.

Furthermore, as part of the InCSEB project, we have erected two full-scale building prototypes, as depicted in Fig. 4, integrating the five newly developed metallic building envelope systems with wood fiber insulation. Over the course of two years, these prototypes are subjected to real environmental conditions, allowing us to assess their performance and assembly feasibility. At project completion, the dismantling feasibility of these prototypes will also be evaluated, contributing to our understanding of sustainable construction practices.

Figure 1 – Testing of sandwich panels

Figure 2 – Teaching of steel construction

Figure 3 – Shear test of the wood fibre sandwich panel

Figure 4 – Two building prototypes at TU Darmstadt

Joris Ide Group

Joris Ide Group is a strong European player in the steel business. Over 4 decades, Joris Ide has developed a clear presence in more than 15 countries leading to operate from 19 production sites and to provide quality steel construction materials. Joris Ide Group offers solutions to a wide range of sectors: agriculture, industrial, residential, and more.

Today Joris Ide Group is one of the major manufacturers in Europe with the help of more than 1400 employees working to deliver sandwich panels, profiles, trays, purlins, planks, and cassettes for building envelop application. Actual production is around 425,000 tonnes of steel.

Joris Ide Group deliver products covered by harmonised standards (e.g., EN 14509 for sandwich panels, EN 14782 or EN 1090-1 for profiles) or under national assessments (e.g., French Technical Assessment) and develop them continuously in accordance with the evolution of the reglementary and standardization environment. To ensure this, Joris Ide Group is a member of trade association like l’Enveloppe Métallique du Bâtiment (EMB), in France, Infosteel in Belgium, or PPA-Europe and ECCS for Europe, and participates actively to the evolution of standards and technical assessments.

Engineers of Joris Ide are members of National delegation in CEN sub-committees (CEN/TC 250/SC 3, CEN/TC 250/SC 3/WG 21, CEN/TC 250/SC 4…) and participate to the work of Belgium and French mirrors group for various standards dealing with design, CE mark (UNM AC 34 and CNC2M in France). Peoples of Joris Ide are experts recognized in France for analyse innovative products (Expert Group 3.1 and 5.2 in CSTB). Thanks to its expertise, Joris Ide participated to experimental programmes and technical studies on profiles and sandwich panels (seismic tests, purlin/rail local maintain test…), to 2 RFCS projects GRISPE and GRISPE PLUS and other national projects (PACTE in France, etc.).

Environmental issues are a big challenge for Joris Ide Group:

- With the program Planet Passionate, established in 2020, Joris Ide Group is setting himself even more challenging goals for the next 10 years, committing to hard targets in the areas of energy, carbon and water reduction while enhancing the circularity of our products.

- With the help and support of the EMB and PPA-Europe, obtaining EPDs for sandwich panels and profiles, and more that 35 FDES “French EPD” published on INIES database.

The main targets of Joris Ide Group are:

- Make a significant reduction in company’s environmental footprint,

- Enhance the environmental performance of its products,

- Make a meaningful contribution towards the achievement of the UN Sustainable Development Goals (SDGs)

The involvement of Joris Ide Groupe in the INCSEB project was an obvious choice, as it represents an important first step in the development of low-carbon solutions for the building envelope.

Please find further information on our website

www.joriside.com

Key tasks of Joris Ide Group within the InCSEB project

Member of the consortium as an industrial partner, the role of the Joris Ide Group is to carry out different tasks which are based on the development of the 3 following 3 site assembled solutions with wood fibre insulation (Working Packages 2 & 3) : a flat roofing system, a double skin cladding system and a façade cladding system.

These tasks are:

- The design, production, and delivery of steel products and accessories to perform tests and realisation of the envelope of one of the two demonstrators,

- The design, production, and delivery of steel frames for the two demonstrators,

- Providing all technical support to perform test including cads, dedicated mounting instructions, and comments on tests reports,

- Making 3 generic BIM objects,

- Establishing design guides and generic mounting instructions for the 3 site assembled solutions,

- Active participation to scientific articles and to all technical discussions.

Tecnalia

Tecnalia is the largest centre of applied research and technological development in Spain, a benchmark in Europe and a member of the Basque Research and Technology Alliance.

It collaborates with companies and institutions to improve their competitiveness, people’s quality of life and achieve sustainable growth, thanks to a team of more than 1,500 people committed to building a better world through technological research and innovation. That is why Tecnalia’s research has a real impact on society and generates benefits in the form of quality of life and progress.

The Lab Services Division of Tecnalia provides testing, calculation, assessment, consultancy, modelling & simulation and/or product certification services as well as technical support and expertise. It has several laboratories related to the Construction Sector, starting from the characterization of materials, going through products up to constructive systems, checking all the essential requirements included in the CPR 305/2011 (structural safety, fire performance, health & environment, safety in use, thermal, acoustics, etc.) and similar international regulations.

Tecnalia is recognised in the sense of the CPR as a Notified Body for testing and Third-Party Certification body for all the necessary tasks to obtain mandatory CE marking. In addition, it is member of EOTA and therefore recognised as TAB, for the voluntary CE marking of innovative and non-standardised products and systems.

Standardisation is also part of the regular work of the Lab Services Division and most of the staff members are involved in several CEN, ISO or national mirror committees. Tecnalia is part of EGOLF, the European organisation for fire labs, where knowledge transfer and mutual recognition between all members allow us to be up to date regarding fire science innovations.

Tecnalia has accredited labs (accreditation scope ENAC LE/024) to perform several tests related to reaction to fire of materials and products (i.e., Euroclasses according to EN 13501-1), fire resistance of solutions and structural elements (i.e., classification according to EN 13501-2), and large-scale fire spread in facades, according to European and American standards (BS 8414, NFPA 285, CAN/ULC S134, etc.). It provides also modelling & simulation services, with CFD tools for fire development and FEM tools for the thermal/mechanical performance of structures.

Please find further information on our website

www.tecnalia.com

Responsibility of Tecnalia in the INCSEB project

The responsibility of Tecnalia in the INCSEB project is mainly focused on the performance evaluation of the envelope systems created within the project, using laboratory tests, calculations, or modelling, and considering the following aspects: fire performance (reaction to fire, resistance to fire, fire propagation or smouldering phenomena), thermal and hygrothermal performance, air and water permeability, seismic behaviour, wind resistance, durability of materials, etc.

Monopanel

Founded in 1961, Monopanel is one of the pioneering European companies in the manufacturing of steel roofing and cladding elements, with know-how recognized by construction professionals, and a wide range of products adapted to the needs and evolutions of the market (decking systems, roof and cladding profiles, liner trays, PIR foam and mineral wool sandwich panels).

2022 marks a new turning point for Monopanel, which continues its history alongside Bremhove SA, an industrial holding company managed by Joris & Enzo Ide, wishing to become active in prefabricated insulated steel components. It is in this context that Monopanel has integrated a third production site in Cerizay, in addition to the production sites of Chauny and Portes-Les-Valence.

With more than 50 years of experience, Monopanel puts quality and service at the heart of its activity by supporting its customers at all stages : project, production, delivery and after-sales service including technical support. Our strenght lies in our ability to develop collaborative and trusting relationships that promote the success of our partners.

Please find further information on our website

www.monopanel.com

Key tasks of MONOPANEL within the InCSEB project

MONOPANEL is one of the key industrial partners of the INCSEB project, in charge of the design, production and delivery of the two prefabricated steel envelopes made of sandwich panels with a wood fibre insulation core.

Furthermore, MONOPANEL has provided all the technical support including :

- drawings of the test set-up to INCSEB lab’s partners in charge of testing all the performances of the solutions ;

- providing all the technical documentation required by building market to deliver a viable and ready-to-use solution.

MONOPANEL has also been actively involved in the erection of the full-scale building prototypes built with sandwich panels, by providing the mounting guide.

Universidade de Coimbra

The University of Coimbra (UC) (www.uc.pt) is a Portuguese public higher education institution created in 1290. It embraces ten faculties, covering all fields of knowledge, complemented by several units that support cultural, sports and education activities.

The University of Coimbra is part of an UNESCO World Heritage place “UC, Alta and Sofia” and promotes an active Agenda towards a carbon neutral institution within its 124+ buildings. UC excels in Education (36 undergraduate degrees, 123 MSc degrees and 72 Doctoral programs), Research, and Innovation and Entrepreneurship (with a dedicated unit, UC BUSINESS), in an International framework.

Research is organized in 5 Strategic Areas, 39 Research Centres (including the research center involved in this project: ISISE) and 15 Technological Platforms.

The Institute for Sustainability and Innovation in Structural Engineering (ISISE) (https://isise.net/ ) is a research unit funded by the Portuguese Science Foundation (FCT), incorporating the Universities of Coimbra and Minho as hosting institutions.

The research center comprises 80 full-time integrated researchers with PhD, and 20.6 M€ in competitive funding (2017-2021). In 2020, ISISE was evaluated by FCT – the Portuguese Foundation for Science and Technology and graded EXCELLENT.

Tasks in INCSEB

In INCSEB project, UC is responsible for the following main tasks:

- Experimental campaign to analyse the diaphragm behaviour of the different types of panels in WP1 and WP2;

- Installation of different types of sensors (thermal flux, humidity and temperature) in both full-size prototypes and monitoring of data over time (WP3);

- Acoustic tests of panels at the laboratory (WP1 and WP2) and ‘in situ’ (in the prototypes) (WP3);

- Determination of benefits, in terms of carbon footprint, of an office building with the different panels developed in INCSEB (WP4).