Development of a new family of steel envelope systems that meet the low carbon construction requirements

The INCSEB European research project (1 August 2021- 31 July 2025), aims at developing five innovative ultra-low carbon building steel envelope systems thanks to the innovative use of wood fiber, a renewable and bio-sourced insulation material, while achieving a high level of thermal performance and ensuring compliance with other requirements such as mechanical, fire and acoustic performances.

5 new steel envelop systems

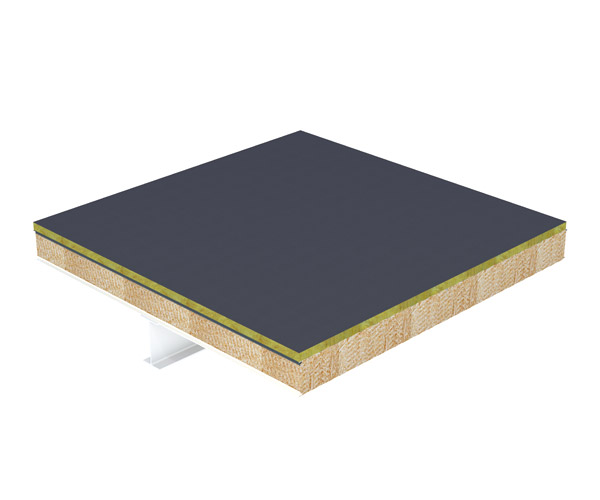

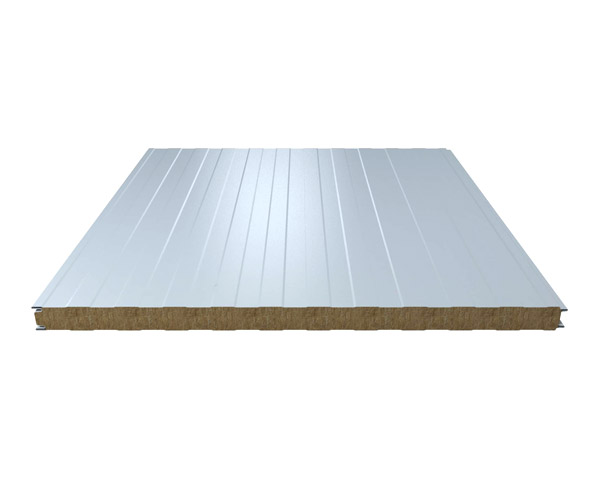

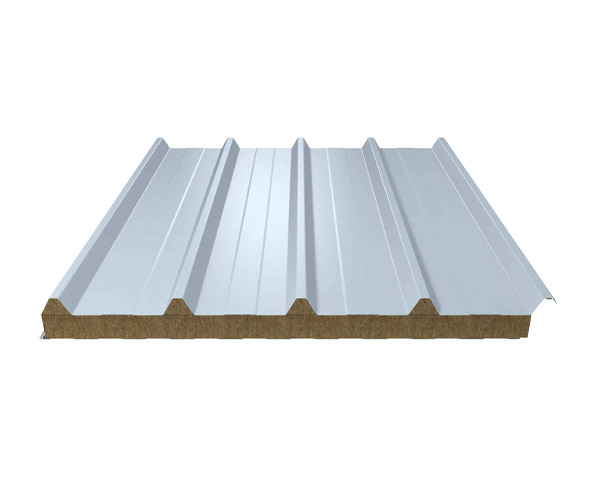

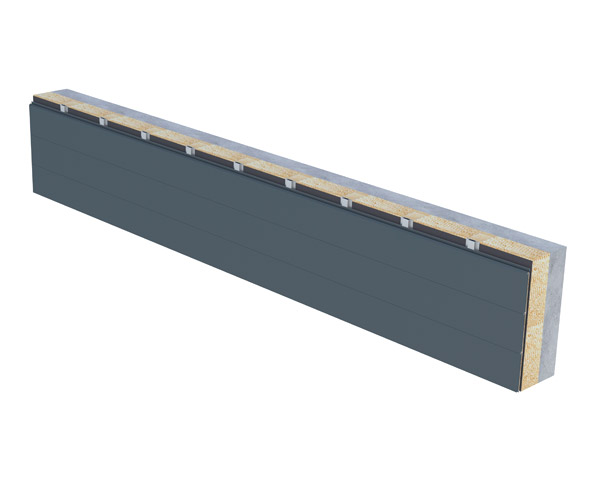

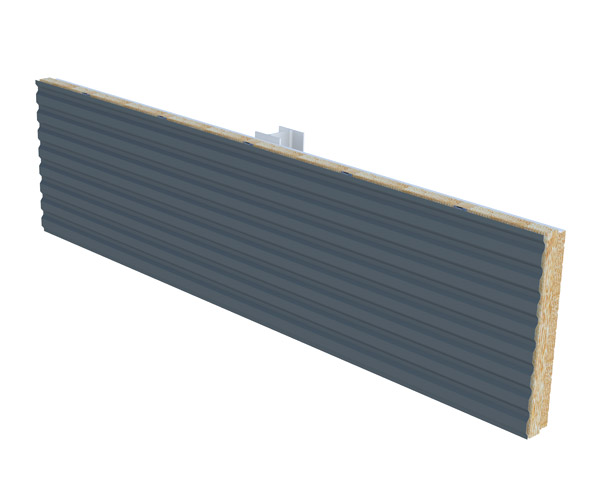

This new family of steel envelop consists of three cladding systems (double skin, façade cladding with cassettes and sandwich panels) and two roofing systems (flat roof sandwich panels and pitch roof sandwich panels).

They could have many applications, particularly for non-residential buildings: industrial and logistics buildings, offices, shopping centers, gymnasiums, sports centres, etc.

Facade cladding with cassettes

Double skin system

Six partners are involved in the project

L’ENVELOPPE METALLIQUE DU BATIMENT (FRANCE) as a project’s coordinator, JORIS IDE NV (BELGIQUE), MONOPANEL SAS (FRANCE), TECNALIA RESEARCH AND INNOVATION (SPAIN) TU DARMSTADT (GERMANY) and UNIVERSITY OF COIMBRA (PORTUGAL)

The challenge:

Meeting low-carbon requirements and all other construction requirements at the same time

The main challenge for this new and innovative family is to meet the new carbon requirements and, at the same time, all the other performance requirements such as thermal, mechanical, reaction and resistance to fire, acoustic, durability, …

How are the performances of these 5 new systems studied?

For what concerns carbon performance, it is studied from two angles:

- For each of the system, all the indicators of life cycle assessment (LCA) are determined.

- An evaluation of the benefits obtained in terms of carbon footprint (GWP) is also assessed by comparing the GWP of an existing office building equipped with a traditional steel envelope system (sandwich panels with PU core) with the same building equipped (by calculation) with the new systems.

To study all the other performances for each of the new systems, an extensive series of tests and calculations according to relevant EN standards is carried out in order to evaluate their mechanical, thermal, fire and acoustic performances together with their air, vapour and water permeability.

In addition, the behavior and durability of the five innovative systems in real life conditions is studied. Indeed, two full scale building prototypes fitted with the new systems are built in Germany and exposed for two years to the rigors of the outside environment.

In addition, the behavior and durability of the five innovative systems in real life conditions is studied. Indeed, two full scale building prototypes fitted with the new systems are built in Germany and exposed for two years to the rigors of the outside environment.

To facilitate the industrial application of the new systems, a series of tools are also developed. For example, a number of pedagogical guides for designing and installing the news systems, including recommendations for their dismantling in view to recycling or reusing them will be prepared. Generic BIM objects, for each of the system, will be also produced.

Two building prototypes at TU Darmstadt